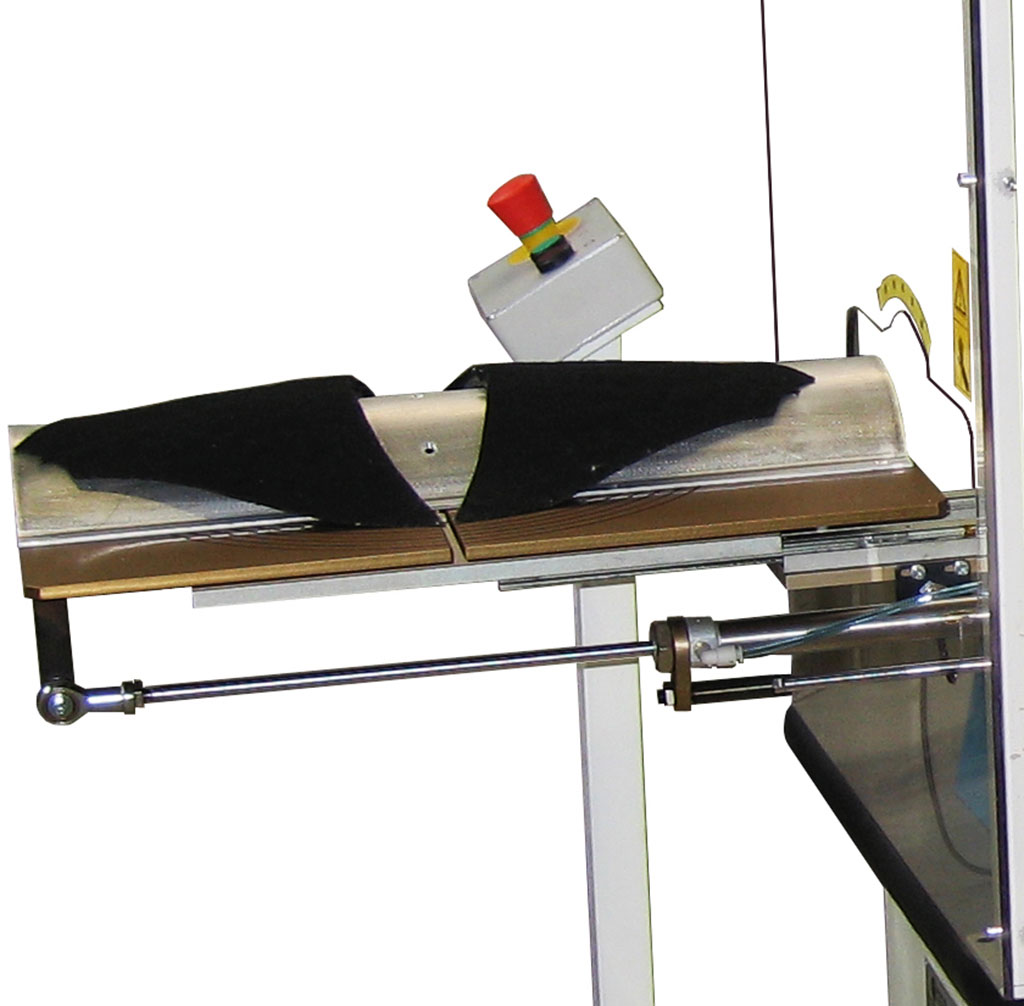

A joystick allows memorization of a wide variety of stitching patterns on a self-learning basis. In this way, each stitching pattern may be programmed to have a variable number of stitches and the distance between them may be adjusted as desired.

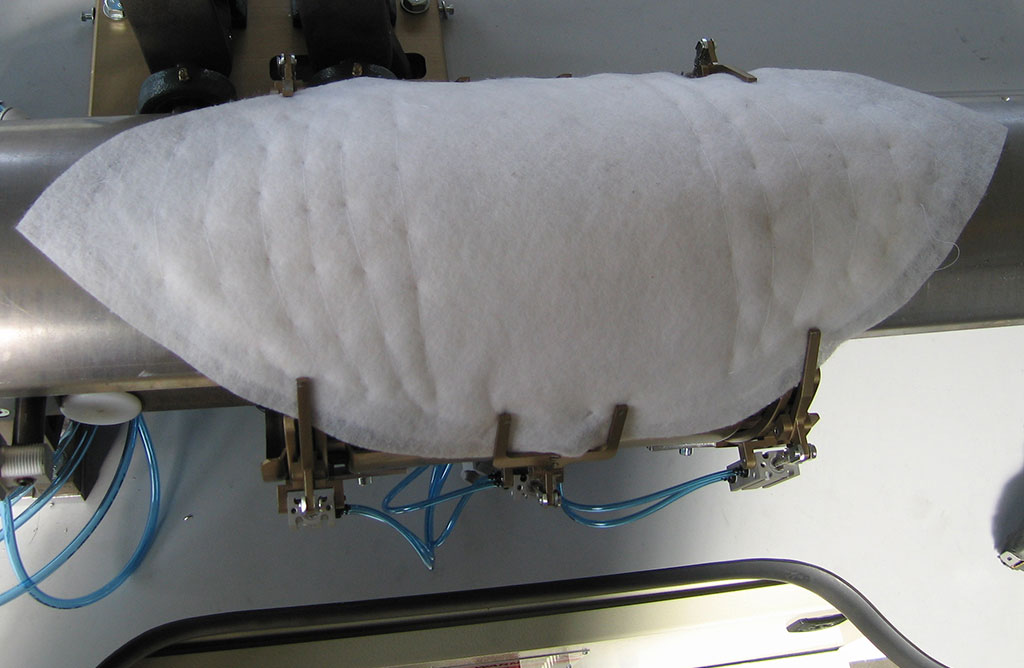

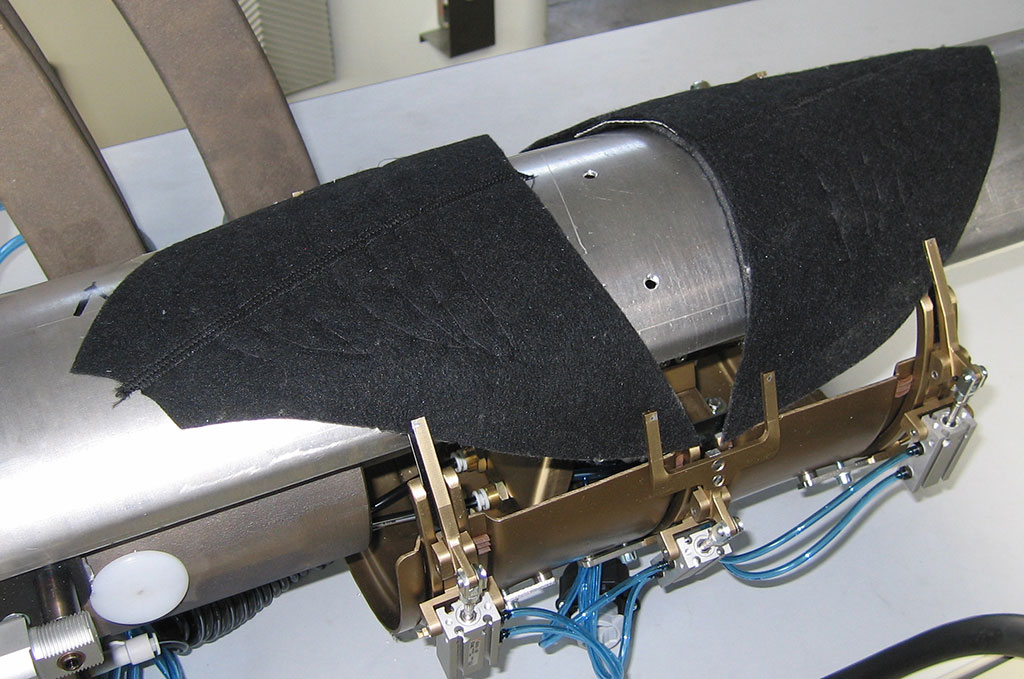

This versatile machine also makes it possible to add or remove stitches at any stage during the program or at the end of the program and has a pick-up unit for loading and unloading the shoulder-pad onto a sliding clamp unit.

This clamp unit will carry the pad into the sewing area for sewing purposes and take it away from it when sewing has been completed.

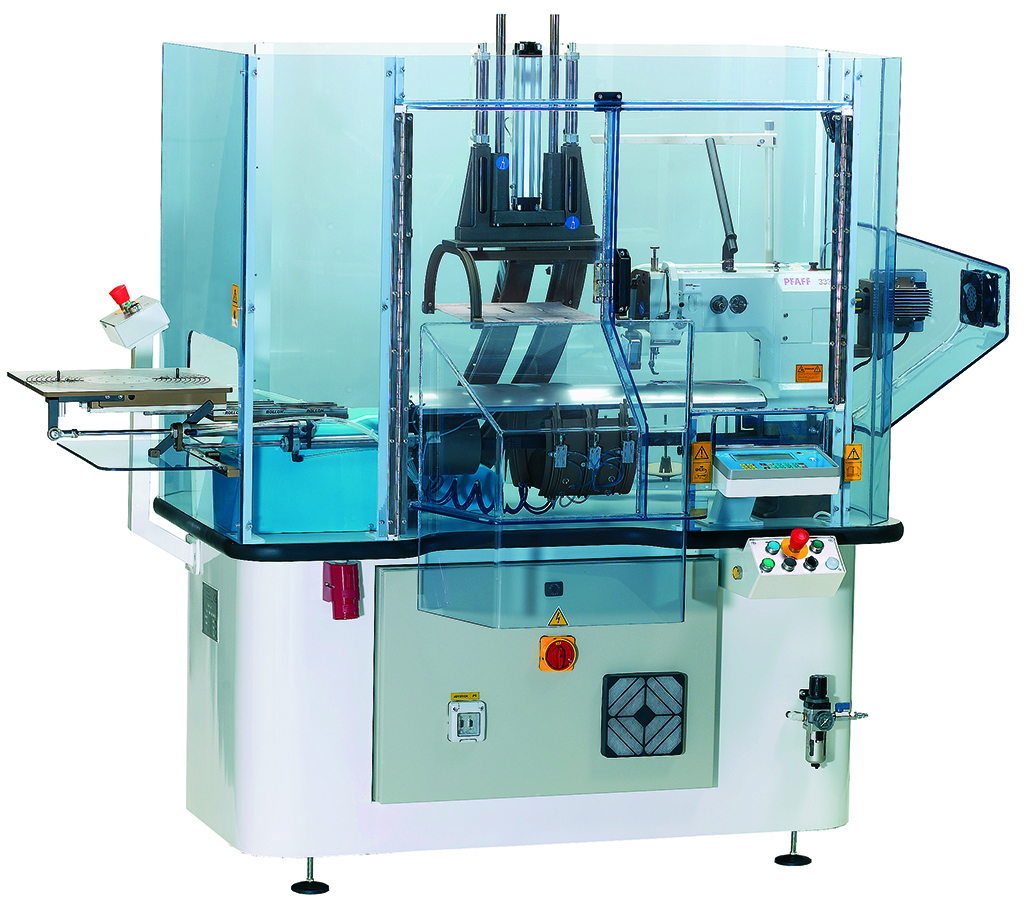

Once the shoulder-pad has been sewn, the thread is automatically cut and the shoulder-pad expelled from the machine.

All these operations are fully controlled by an electronic programmer with a built-in display.

Machine is equipped with a PFAFF 333 sewing machine, complete with electronic stop and rotating speed converter for speed adjustment of the sewing head, PenDrive for transferring programs to a PC or to other machines.

It is also possible to sew some of the stitches within a program or to correct possible mistakes in the stitching by running the program at a slower speed than set (for example, the double-stitching at the beginning or end of a program, the double stitching halfway through a program to pass from the right shoulder-pad to the left piece as well as some stitches within the program may be sewn at a slower speed for better control).

Model P396-3A makes it possible to sew with an axis movement of 95 mm.

The sewing range of this machine is about 31 cm in length and about 27 cm in width.

The piece to be sewn is laid upon a plate from which it is lifted by an automatic pick-up unit and then laid onto a movable clamp-unit.

Thanks to the synchronized movement of the two axes, the shoulder-pad will be shifted in the sewing unit as the sewing program loaded.

At the end of the sewing the thread cutter automatically cuts the thread and then air blowing unload the shoulder-pad in front of the machine.

MC mod. P111 – Automatic Sewing Machine for Shoulder Pads Curving 95 mm

Technical Data

– As many as 147 programs with up to 500 stitches each can be stored in the memory

– Visualization of cycle memory

– Visualization of cycle time

– Total count of stitches per program

– Total count of cycles performed

– Programmable count for spool replacement

– Upper thread control: the machine will stop if the thread snaps or if the needle gets unthreaded

– Manual control of all functions

– Power 400V 50/60 Hz (three-phase + neutral + earth)

– Working temperature: 10 ÷ 35 °C

– Air pressure: 5 atm

– Production output: 250 to 300 pairs of shoulder-pads per hour (this number may vary according to the kind of fabric used for the shoulder-pads, the thickness of the shoulder-pad, the type of thread used, the type of stitching pattern chosen, etc.)

– Dimensions: cm. 209 x 115 x H180

– Weight: Kg. 380

Note: Memorization of the sewing program does not require any skilled labor, as it takes place on a self-learning basis. Even an ordinary worker can memorize a program in 2 or 3 minutes and then immediately run it in automatic mode.

Coupled Cones

Coupled Cones Marron Glacés

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

Bag Filters Flexible Control Cable

Flexible Control Cable