Chocolate Coating Equipment

Machine coats chocolate the waffle cones for an adjustable height and decorates them.

It is composed of the following parts:

– a melter tank with a capacity of 150 Lt

– a chain conveyor with grippers, consisting of plates, each of which is equipped with 8 grippers suitable for blocking any type of waffle cone

– a loading plate with No. 8 lanes for loading the waffle cones (having an autonomy of about 5 min)

– a loading unit that takes and inserts the waffle cones in the grippers of the chain conveyor

– a system to check the condition of the waffle cones in the grippers immediately after loading

– a system for aligning the waffle cones in the conveyor gripper chain

– a tank for chocolate, in which the waffle cones come dipped

– a system to coat the waffle cones in the following options: inside and outside for an adjustable height, only outside for an adjustable height, completely inside, completely inside and just externally for an adjustable height

– a system to put the sprinkle on the waffle cones: deposit does by falling, perpendicularly on their surface, while they turn on themselves;

– a unit for the recovery of excess sprinkle

– a cooling tunnel

– a unit for unloading the waffle cones from the chain conveyor and depositing them on the 8 lane unloading conveyor belt

– electrical panel with PLC and touch-screen for complete machine management

Solid chocolate come put into the melter tank, brought to the melting temperature and then discharged by the pump until into the tank for chocolate, where the waffle cones come dipped.

After this operations, waffle cones are stacked on the conveyor belt.

Machine is equipped with grippers, suitable for blocking many models of waffle cones of different size and taper.

Machine must be followed by at least 3 operators: 1 operator has the task of loading the waffle cones in the loading plate with No.8 lanes, while the other 2 operators must take the stacks of the processed waffle cones present above the conveyor belt, and put them inside the boxes for packaging .

EM 208-4500 REV6 – Enrobing Machine for Waffle Cones

Technical Data

– Maximum production capacity is approximately 4500 pieces / hour

– Autonomy of the loading plate with No. 8 lanes about 5 min

– Load capacity of the melter tank: 150 Lt

– Power supply: 400V, 50Hz, 12Kw, 12A

– Pneumatic supply: 5 bar

– Dimensions: cm. 610 x 330 x H180

– Weight: 2200 Kg

Note: Please note that the data included is not binding.

Coupled Cones

Coupled Cones Marron Glacés

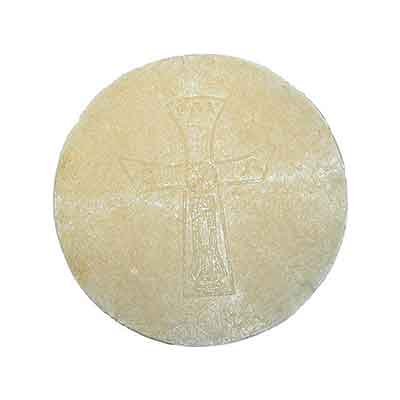

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

Bag Filters Flexible Control Cable

Flexible Control Cable