This wadding machine is completely automatic and was especially designed to meet different demands. This machine is commanded by an electronic programmer where the user can execute the manual commands of all the movements and a joystick allows memorization of a wide variety wadding on a self-learning basis.

The user is in charge of feeding the machine by loading No.2 rolls of wadding material (cotton, or cotton + viscose, or cotton + wool, or polyester, etc……) with the same width and grams per square meter.

The roll of wadding must have a maximum width of 25 cm. Machine is made up of a device for unwinding the material which helps slide the wadding into the unit that generates the shape of the padding and by a needle-punching unit (like DILO) which compacts the padding. About 5 minutes needed to change from one type of production to another.

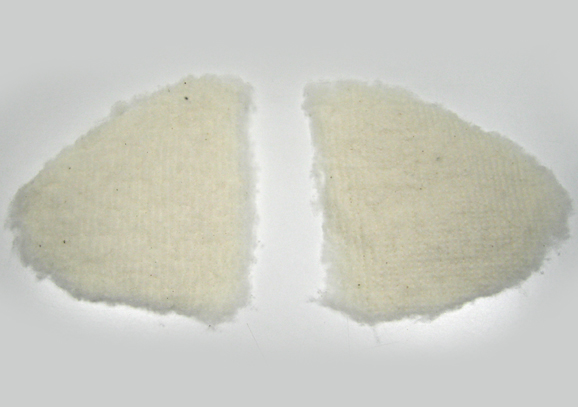

This machine make a single wadding at once like the shape desired (for example triangular, oval, trapezoidal, etc… ): the wadding is conical and the maximum thickness of the wadding at the highest point is about 2,5 cm.

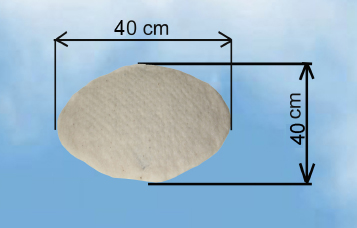

Model 108 makes it possible to obtain padding pieces of a maximum size of about cm. 40×40

IA mod. 108 – Automatic Machine for Producing Wadding for Shoulder-Pads

Technical Data

– As many as 40 programs can be stored in the memory;

– software for transferring programs to a Personal Computer;

– hourly output ranges 500/600 padding, depending on the shape of the padding, its size, the height desired, and also on the type of wadding used (cotton, or cotton + viscose, or cotton + polyester, etc…);

– it is possible to visualize the number of pieces produced, the number of the program being run and many other technical data;

– upper material control: the machine warning when the rolls cotton are ending;

– manual control of all functions;

– power supply is 400V 50/60 Hz (three-phase + neutral + earth);

– Working temperature: 10 ÷ 35 °C;

– Air pressure: 5 atm;

– Dimensions: cm. 380 x 265 x H192;

Note: Please note that the data included is not binding.

Coupled Cones

Coupled Cones Marron Glacés

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

Bag Filters Flexible Control Cable

Flexible Control Cable